Kub Shrink Insulating Tubing

Daim ntawv thov

1.Siv rau nruab nrab voltage mus txog 36kV

2.Kev tiv thaiv kev ya raws thiab siab

3.Suitable rau cable termination thiab intermediate txuas rwb thaiv tsev tiv thaiv

Feature

1.Kub melting nplaum muab zoo waterproof

2.Coating hom: zaj duab xis txheej

3.Excellent corrosion kuj

4.UV tsis kam thiab huab cua tsis kam

5.Halogen-dawb

6.Superior hluav taws xob thiab txhua yam khoom

7.Shrinkage piv 3: 1

8. Phab ntsa nruab nrab

Feature

1.Qhov khoom siv hluav taws xob zoo dua

2. Txhim khu kev rwb thaiv tsev

3.Superior hermetic sealing

4.Excellent tshav kub / txias pov thawj, waterproof, Anti-aging,

5.Widely siv nyob rau hauv lub teb ntawm hluav taws xob fais fab, hluav taws xob, roj av, tshuaj engineering, kev tsim kho thiab kev sib txuas lus

Kev tsim cov cua sov shrinkable tubing yuav tsum xub xaiv qhov tsim nyog masterbatch, thiab tom qab ntawd xaiv cov khoom siv los tsim tshwj xeeb.

Thermal Housing casing.

1. Cov txheej txheem ntawm cov cua sov shrinkable tube yog thawj zaug ntawm kev tsim cov polyene leech masterbatch: sib txuas ntau yam polyene leech puag cov ntaub ntawv nrog ntau yam khoom siv pabcuam.

Cov ntaub ntawv raug hnyav raws li tus qauv sib piv thiab tom qab ntawd sib xyaw: cov ntaub ntawv sib xyaw yog muab tso rau hauv ib qho ntxaib-ntsia hlau extruder thiab pelletized los tsim cov polyene leech functional masterbatch.

2. Cov txheej txheem molding khoom: raws li cov duab ntawm cov khoom, ob txoj kev ntawm ib leeg ntsia hlau extrusion thiab txhaj tshuaj molding yuav siv tau.

Rau kev ua thiab ntau lawm:

1. Ib leeg-ntsia hlau extrusion hom: tsuas yog siv rau extrusion molding ntawm cov kav dej kub, xws li ib leeg-phab ntsa cua sov-shrinkable leeg, ob-phab ntsa cua sov-shrinkable hlab nrog kua nplaum, thiab nruab nrab thickness

Phab ntsa cua sov dab dej kav, siab siab busbar tshav kub dab dej kav, kub kub shrinkable kav thiab lwm yam khoom yog tag nrho cov txheej txheem thiab tsim los ntawm ib tug ntsia hlau extrusion.

Lub tshav kub shrinkable tube ntau lawm kab yuav tsum muaj cov khoom siv hauv qab no: extruder (lub tog raj kheej ua kom sov), pwm ntau lawm, dej txias tank, cov cuab yeej nro, thiab

Disk device, thiab lwm yam.

2. Kev txhaj tshuaj molding: feem ntau yog siv rau kev tsim cov khoom cua sov-shrinkable tshwj xeeb-zoo li qhov chaw, xws li lub kaus mom kub lub tog raj kheej, cov kaus mom kub-shrinkable, kub-shrinkable ntiv tes cots thiab lwm yam khoom.

Lawv txhua tus siv kev txhaj tshuaj molding, thiab cov cuab yeej tsim khoom yuav tsum suav nrog kev txhaj tshuaj molding tshuab thiab txhaj tshuaj pwm.

3. Cov kauj ruam tseem ceeb tom ntej yog hluav taws xob sib txuas.Cov khoom tsim los ntawm extrusion lossis txhaj tshuaj molding tseem yog linear molecular qauv.

Cov qauv, cov khoom tseem tsis tau muaj "kev ua haujlwm nco", thiab kev ua haujlwm ntawm qhov kub thiab txias, kev laus ua haujlwm, thiab hnav tsis kam yog tsis txaus.

Hloov cov qauv molecular ntawm cov khoom.Txoj kev peb feem ntau siv yog hluav taws xob crosslinking kev hloov kho: electron accelerator hluav taws xob crosslinking, cobalt qhov hluav taws xob

Kev sib txuas sib txuas, peroxide tshuaj sib txuas sib txuas, lub sijhawm no cov molecule hloov los ntawm cov qauv linear molecular mus rau lub network qauv.Cov khoom extruded yog dhau

Tom qab kev sib txuas sib txuas, nws muaj "nco nyhuv", uas zoo heev txhim kho qhov kub thiab txias, cov khoom siv hluav taws xob, thiab cov khoom siv tshuaj lom neeg ntawm lub tshav kub shrinkable raj.Lub rooj tshwj xeeb

Tam sim no lub rhaub dej kub tau hloov pauv los ntawm lub xeev ntawm kev ua siab ntev mus rau qhov tsis sib xws, kev laus ua haujlwm, kev ua haujlwm tsis zoo, thiab tshuaj tiv thaiv corrosion.

4. Expansion molding: Cov khoom hloov los ntawm hluav taws xob crosslinking twb muaj "zoo li lub cim xeeb", thiab nws muaj qhov siab.

Tsis-melting kev ua tau zoo nyob rau hauv qhov kub thiab txias.Tom qab cua sov ntawm qhov kub thiab txias, lub tshuab nqus tsev thiab cua txias, nws ua tiav cov cua sov shrinkable raj, thiab tom qab ntawd raws li lub raj.

Qhov teeb meem tiag tiag ntawm cov khoom tiav ntim thiab kaw kuj tuaj yeem txiav thiab luam tawm raws li cov neeg siv khoom xav tau.Tsis zoo li qub ntim kuj muaj.

Kev ua tau zoo

| Kuaj | Txoj Kev Xeem | Kev xav tau |

| Ua haujlwm kub | TIAB SA 224 | -50 rau + 125 ℃ |

| Tensile zog | ASTM D 2671 1 | ≥14 Mpa |

| Elongation thaum so | ASTM D 2671 1 | ≥400% |

| Elongation ntawm so tom qab tshav kub laus | ASTM D 2671 158 ℃ / 168 teev | ≥300% |

| Longitudinal shrinkage | TIAB SA 224 | 0 ± 5% |

| Ib nrab phab ntsa tus nqi | ASTM D 2671 1 | 30% |

| Nplaim retardancy | VW-1 | Hla |

| Volume resistivity | TSI 93 | > 1014Ω.m |

| tooj liab stability | TSI UL224 | Hla |

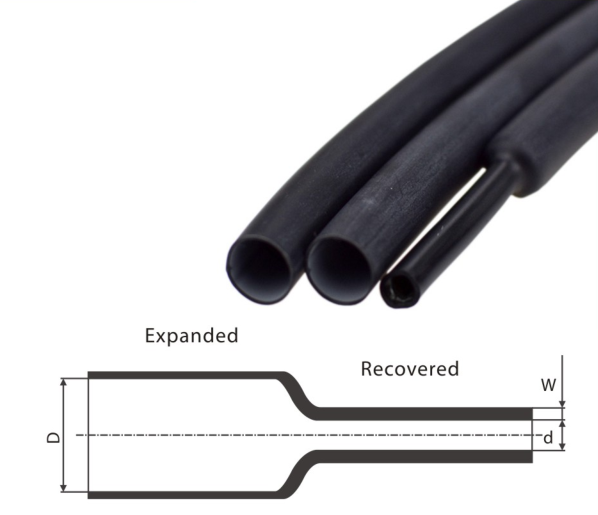

| Hom | Daim Ntawv Thov Diameter Range (mm) | Kev nthuav dav (mm) | Rov qab (mm) | |

| D (min) | d (max) | W (min) | ||

| RSG-15/5 | 4.5-8 | 15 | 5 | 1.5 |

| RSG-20/8 | 6.5-14 | 20 | 8 | 1.8 |

| RSG-28/10 | 12-18 | 28 | 10 | 1.8 |

| RSG-35/14 | 17-27 | 35 | 14 | 2 |

| NWS 10-28/10 | 6.5-14 | 28 | 10 | 2.2 |

| NWS 10-34/14 | 17-27 | 34 | 14 | 2.3 |

| NWS 10-40/18 | 17-30 : kuv | 40 | 18 | 2.5 |

| WRSG10-50/20 | 17-35 : kuv | 50 | 20 | 2.5 |

| WRSG35-50/20 | 17-35 : kuv | 50 | 20 | 3 |

| WRSG35-60/22 | 21-45 : kuv | 60 | 22 | 3 |

| WRSG35-70/25 | 24-52 : kuv | 70 | 25 | 3 |